What is 1.2767 Steel ? 1.2767 steel is a high-carbon tool steel known for its excellent hardness, wear resistance, and toughness. 1.2767 material is commonly used in a variety of industries such as automotive, manufacturing, and aerospace due to its versatility and reliability.

DIN 1.2767 Tool Steel Specification and Equivalent

1.2767 grade steel is a hot work tool steel that is equivalent to DIN 45NiCrMo16 and AISI 6F7 steel. It is typically available in rounds, flats, and plates. Currently we supply 1.2767 round bar and flat bar to Asia and European countries.

1.2767 Steel Chemical Composition

The chemical composition of grade steel 1.2767 as per DIN ISO 4957 standard is as follows:

- Carbon (C): 0.40-0.50%

- Silicon (Si): 0.10-0.40%

- Manganese (Mn): 0.20-0.50%

- Chromium (Cr): 1.20-1.50%

- Nickel (Ni): 3.80-4.30%

- Molybdenum (Mo): 0.15-0.35%

DIN Steel 1.2767 Mechanical Properties

DIN 1.2767 materials offers excellent mechanical properties, including high toughness, wear resistance, and hardness. Here are the typical mechanical properties of 1.2767 steel:

- Tensile strength: 1100-1250 MPa

- Yield strength: 900-1000 MPa

- Elongation: 12-14%

- Hardness: 56-60 HRC

1.2767 Steel Heat Treatment

1.2767 material steel can be heat treated to achieve desired properties. The recommended heat treatment for 1.2767 tool steel is as follows:

610 to 650 °C for about 2 to 5 hours slow controlled cooling of 10 to 20 °C per hour to about 600 °C further cooling in air, max. 260 HB

- Hardening

840 to 870 °C

Quenching in oil/hot bath/air

Obtainable hardness: 53-58 HRC

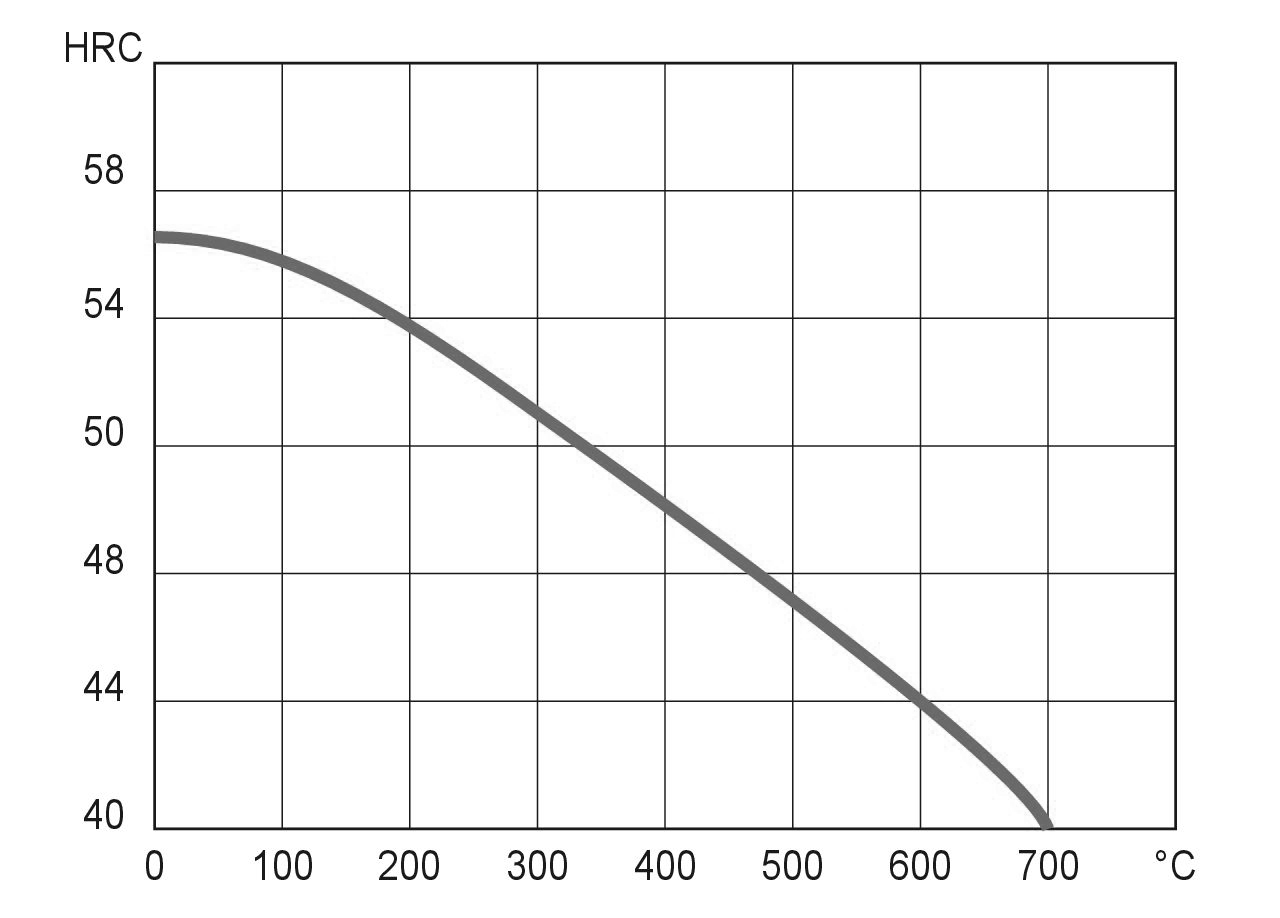

- Tempering

Slow heating to tempering temperature immediately after hardening. Minimum time in furnace: 1 hour per 20 mm part thickness. Tempering twice is recommended.

Annealing graph:

DIN 1.2767 Material Application and Use

1.2767 tool steel is commonly used in the manufacturing of cutting tools, dies, and punches due to its high hardness, wear resistance, and toughness. It is also used in the production of plastic molds and forging dies. Additionally, 1.2767 grade steel can be used in the automotive and aerospace industries for various applications, including shafts, gears, and connecting rods.

In conclusion, grade 1.2767 is a versatile high-carbon tool steel. 1.2767 tool steel has excellent properties that make it suitable for various industrial applications. Its hardness, toughness, and wear resistance make it ideal for use in cutting tools, dies, and punches, while its versatility allows for use in automotive and aerospace applications.

Both 1.2767 flat bar and round bar are available here in Otai. Welcome to send your detailed inquiry to us anytime.