ASTM A681 specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products, which include hot or cold finished steel bar, steel plate, steel sheet, strip, rod, wire, or forgings etc.

Material in accordance with ASTM A681 specification is classified by chemical composition. There are Hot Work Tool Steel, Cold Work Tool Steel, Shock-Resisting Steels, Special-Purpose Tool Steels, Plastic Mold Tool Steel. Common steel grades: H11, H13, A2, D2, D3, O1, P20 etc.

1.2210 Steel: Chrome-Vanadium alloyed Cold-work Silver Steel

DIN 1.2210 steel is a Chrome-Vanadium alloyed cold-work steel. It's also called as silver steel. It's known for its high wear resistance and toughness.

H14 Steel: A Hot Work Tool Steel per ASTM A681

H14 steel is known as a high-speed tool steel, recognized for its notable wear resistance, strength, and toughness. It's typically used in the creation of cutting tools, dies, and various forms of machinery where its superior characteristics are beneficial.

1.2367 Steel: Your Ultimate Guide to This Superior Material

DIN 1.2367 steel, also known as X38CrMoV5-3, is a hot work tool steel characterized by its exceptional toughness, high-temperature strength, and excellent resistance to heat-checking. These characteristics make it particularly suitable for high-pressure die casting and extrusion.

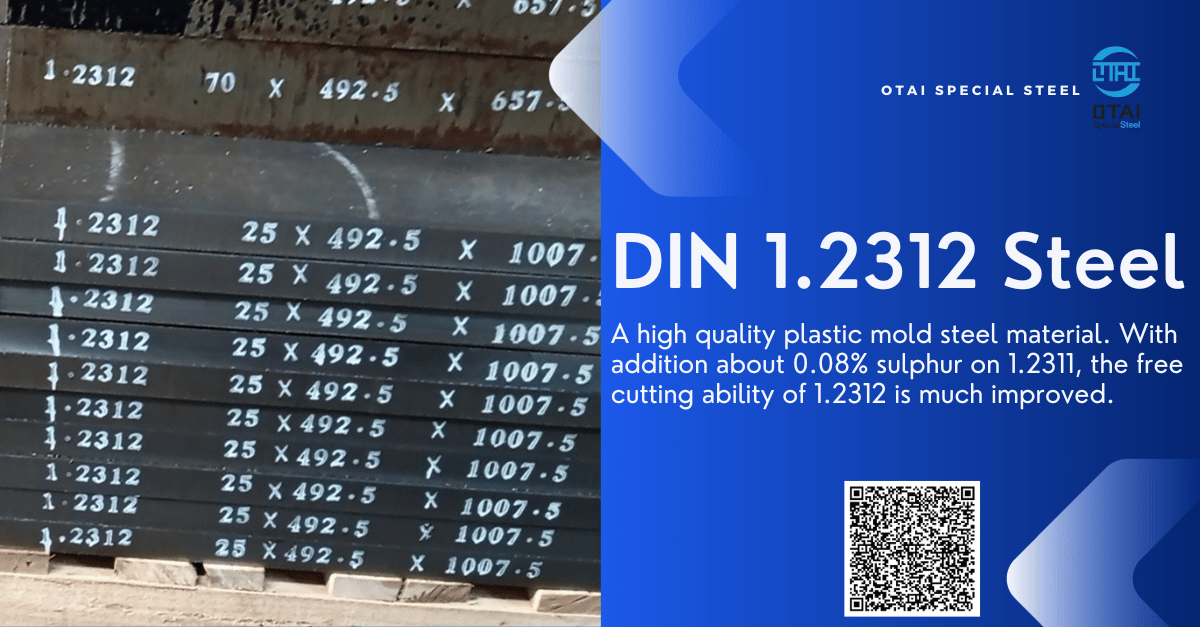

1.2312 Steel | P20+S Steel

DIN 1.2312 steel is a high quality plastic mold steel material. Steel 1.2312 is material produced by add about 0.08% sulphur on material 1.2311. The S element improves free cutting ability of 1.2311 steel. DIN 2312 material is usually delivered in pre-hardness condition and hardness 28~34HRC. ASTM P20+S steel is equivalent to DIN 1.2312 [...]

DIN 1.2083 | AISI 420 Mold Steel

DIN 1.2083 steel is chromium alloyed stainless plastic mold steel. It is equivalent to AISI 420 steel. The steel 1.2083 is a major steels for hot pressing in circulation. 1.2083 stainless steel is generally supplied annealed condition with a hardness < 230HB. It can also be delivered ESR and quenched and tempered to 320 [...]

DIN 1.2738 Steel | AISI P20+Ni Tool Steel

DIN 1.2738 steel is one kind of plastic mold steel, equivalent to AISI P20+Ni tool steel. While Nickel, chromium and molybdenium are the alloying elements for hardness and toughness. 1.2738 tool steel is specially designed for plastic mold industry, especially for big steel mold parts. DIN 1.2738 tool steel is usually supplied as pre-hardened/quenched [...]

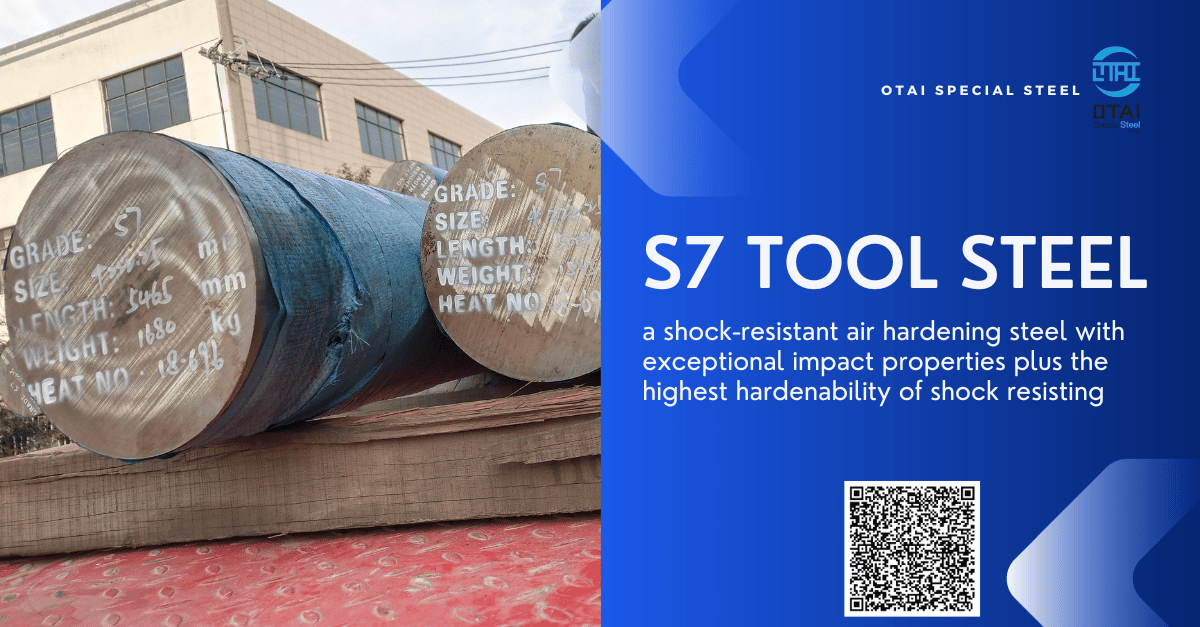

AISI S7 Tool Steel | 1.2355 | 50CrMoV13-15

AISI S7 tool steel is a shock-resistant air hardening steel. AISI S7 steel has exceptional impact properties plus the highest hardenability of shock resisting grades of tool steel.

AISI O2 Tool Steel | 1.2842 | 90MnCrV8 | BO2 Steel

AISI O2 Steel is an oil hardening tool steel supplied in the annealed condition. ASTM O2 steel is widely used for universal use. It's similar to AISI O1 grade tool steel, with addition of Mo element.

AISI D6 Tool Steel | 1.2436 | X210CrW12 | SKD2 Cold Work Steel

AISI D6 tool steel is a 12% chromium alloy cold work tool steel.We supply good quality of AISI D6 and equipvalent DIN 1.2436/X210CrW12 or JIS SKD2 steels.

NAK80 Steel | P21 | 10Ni3MnCuAl Mold Steel

NAK80 steel is a precipitation or age-hardened mold steel with a uniform through hardness of approximately 40 HRC. Otai steel supplies NAK80 mold steel for high end plastic mold steel.

L6 Tool Steel | 1.2714 | 55NiCrMoV7 | SKT4 | BH224/5

AISI L6 Tool Steel is one of alloy, oil-hardening tool steel in ASTM A681 standard. Some equivalent steel is 1.2714, 55NiCrMoV7, SKT4, BH224/5 steel.

A2 Tool Steel | 1.2363 | X100CrMoV5 | SKD12 | BA2 Steel

ASTM/AISI A2 tool steel is a versatile, air hardening chromium alloy tool steel that replaces O1 tool steel when safer hardening, less distortion and increased wear resistance are required.

ASTM H12 Tool Steel | 1.2605 | X35CrWMoV5 | SKD62 | BH12

AISI H12 steel is a 4.75~5.5% chromium, general-purpose hot work tool steel. ASTM/AISI H12 Steel is a deep-hardening, air-hardening steel that exhibits minimal size change during heat treatmnet.

AISI H11 Tool Steel | 1.2343 | X37CrMoV5-1 | SKD6 | BH11

AISI H11 tool steel is a 5% chromium hot work tool steel. H11 tool steels have the higher toughness, with some reduction in wear resistance and temper resistance.

ASTM H10 Tool Steel | 1.2365 | 32CrMoV12-28 | SKD7 | BH10

H10 Tool Steel is one chromium hot-work tool steel that exhibits excellent resistance to softening at elevated temperature. H10 tool steel is recommended for difficult hot work tooling applications.

O1 Tool Steel | 1.2510 | 100MnCrW4 | SKS3

AISI / ASTM A681 O1 Tool Steel is a low alloy cold work tool steel that must be oil-quenched in heat treatment. Tools and dies made from O1 Flat Ground will have good wearing and abrasive qualities.

D3 Cold Work Steel | 1.2080 | X210Cr12 | SKD1

AISI D3 cold work steel, also know as DIN 1.2080 (Werkstoff) and JIS SKD1, is a 12% chrome alloy steel. D3 cold work steel has very high wear resistance against abrasive and adhesive wear.

P20 Steel Plate | 1.2311 | 3Cr2Mo | Plastic Mold Tool Steel

AISI P20 Steel Plate Material is a versatile, low-alloy tool steel that is characterized by good toughness at moderate strength levels. The special purpose mold steel P20 steel plate is commonly used for plastic injection mold cavities and tooling.

D2 Tool Steel | 1.2379 | X153CrMo12 | SKD11

AISI D2 tool steel is a high carbon, high chromium tool steel (12% chrome) with extremely high wear resisting properties, heat treatable to 60-62 Rc. D2 is very wear resistant but not as tough as lower alloyed steels.

H13 Tool Steel | 1.2344 | X40CrMoV5-1 | SKD61 Hot Work Steel

H13 Tool Steel is chromium hot-work tool steels. Due to H13 steel excellent combination of high toughness and fatigue resistance, AISI H13 hot work tool steel is used more than any other tool steel in tooling applications.