How to Define a Good 4140 Steel Plate Supplier ?

First, the supplier should be experienced about the 4140 steel grades as per standard of ASTM A29 standard. The chemical composition and other property should be as per standard. This is the basic.

Second, if the supplier keeps 4140 steel plate stock with complete 4140 plate sizes / thickness or not. For example, 4140 sheet, 1.5mm thickness, 5 tons, 12mm, 6tons, 20mm, 5 tons… Then when anytime, customer need different4140 steel sizes with fast delivery, the supplier could process the order in very short time and delivery. Besides, when customer needs 4140 flat bar with different sizes, the supplier should be equipped with band saw to cut to width according to given spec and quantity. Like Otai, there is around 1000 tons stock of 4140 steel plate for customer’s choose.

Third, if the 4140 plate supplier is also able to supply material with different heat treatment condition and hardness, it would be good. Usually, it is usually supplied as 4140 hot rolled condition. Most of stock materials are hot rolled 4140 plate / flat bar. But some customer also need 4140 annealed plate, or Q+T plate with higher hardness. So, if the supplier could supply all different 4140 plate steel. It would be good for customer.

Fourth, if the price of 4140 plate material would be also good. It would be perfect. Or there would be regular 4140 steel plate for sale, it would be much attractive.

What You Should Care for 4140 Steel Material ?

Because it’s very common for 4140 round bar, but it’s not that popular for 4140 steel plate or 4140 flat bar. So, it’s not that easy to find a reliable 4140 steel plate supplier. But when you find it, you should care about something:

Hardness: Hardness of different condition of 4140 plate. Generally, the 4140 annealed plate hardness is max 255HB, while the quenched and tempered (Q&T) plate 28-32HRC (280-320HB). So, when you have requirement of hardness, you should make it clear to supplier, to avoid the wrong material condition.

Properties: When you have special mechanical properties, you would need heat treated plate for sure.

Equivalent: There are 4140 steel plate equivalent steel grades, that is, 42CrMo4 / 1.7225 plate or SCM440 plate. You would need to specify 4140 grade if you don’t accept equivalent. You could see the difference in this post 4140 | 42CrMo4 | SCM440.

Otai is the reliable supplier, also 4140 plate supplier for Bohler / Uddeholm. Reliable supplier with complete range of sizes and ability for heat treatment and cutting to size. Welcome for steel 4140 plate request anytime.

FAQ

How Hard is 4140 Steel?

If you’ve ever found yourself thinking the question, “How hard is 4140 steel?”, you can find the answer here.

What is 4140 Steel?

What exactly is 4140 steel? AISI 4140 grade steel material, often referred to as chromoly steel, is a low alloy steel containing chromium and molybdenum as its primary alloying elements. These elements give it distinct characteristics that make it stand out in the vast world of metals.

The Hardness Factor

Now, onto the main question. The hardness of AISI 4140 steel can vary based on how it’s processed. But let’s break it down:

- Annealed Condition: In its annealed state, 4140 grade material typically has a hardness of around 197 Brinell Hardness Number (BHN). This state is softer and more ductile, making it easier to work with.

- Heat Treated: When 4140 material is done by heat treatment, its hardness can shoot up significantly. Depending on the specific treatment, it can reach hardness levels of up to 28-32 Rockwell C (HRC) for light sections like 4140 PH steel plate hardness and 22-27 HRC for heavier sections.

- Quenched and Tempered: In its quenched and tempered state, SAE 4140 alloy steel can achieve a hardness of 54-59 HRC. This makes it incredibly strong and resistant to wear.

Why Does Hardness Matter?

You might be wondering, “Why all this fuss about hardness?” Well, the hardness of a steel determines its wear resistance and its ability to retain its shape under stress. Imagine using a soft steel for a high-stress component – it wouldn’t last long, would it? Steel that’s too hard can become brittle. So, for How Hard is 4140 Steel?, it’s more important to find the right balance.

Applications of AISI 4140 Material

Given its versatile hardness range, AISI 4140 finds its way into various applications:

- Gears and Bolts: Thanks to its strength and toughness.

- Machine Parts: Where wear resistance and durability are paramount.

- Axles and Shafts: Benefiting from its strength-to-weight ratio.

In Conclusion

So, how hard is 4140 steel? The answer: it depends on its treatment. But one thing’s for sure, its versatility in hardness makes it a go-to choice for many industrial applications. If you have more questions or need further information about 4140 steel or any other steel types, don’t hesitate to drop me an email at jeremy@otaisteel.com or reach out on WhatsApp at +8613610149979. We at Otai Special Steel are always here to help!

What Does 4140 T Steel Plate Mean ? The “T” in 4140 T Steel Plate usually stands for “tempered”. It means that the 4140 steel has been done by heat treatment process called quenching and tempering (Q+T or prehard).

Here’s a brief explanation about this question:

AISI 4140 steel is an widely used alloy steel that contains chromium, molybdenum, and manganese etc. After the 4140 steel is initially rolled, we need to do quenching and termpering to achieve higher properties for different applications. This process is to heat the steel to a high temperature and then cooling it rapidly by sink 4140 steel plate or round bar in a liquid, often oil or water.

This rapid cooling process makes the 4140 steel material very hard, but it also makes it brittle. To release this brittleness, the 4140 steel is then tempered. Tempering process is to reheat the quenched AISI 4140 steel to a lower temperature to allow some of the hardness to be exchanged for increased toughness or durability.

So, when you see 4140 T Steel Plate, it means that you’re looking at a steel plate made of 4140 alloy steel that has been quenched and tempered to achieve a better balance of hardness and toughness. This kind of 4140 steel is often used in applications where strength and durability are paramount.

We Otai can supply you both 4140 plate T and 4140 plate A or as rolled. Please contact us for any further questions.

What is the Hardness of 4140 Plate? Well, it depends on the different condition of 4140 plate you need.

Steel plate 4140 PH (Q+T) condition goes with 28~32HRC hardness usually.

Annealed 4140 plate (A) is with hardness less than 241 HB. It’s easy to do further cut or machining.

4140 plate As Rolled (HR) has not even hardness. It varies from one batch to another batch. But it’s the best to do further heat treatment according to different customer request.

You please tell us your detailed request, we will offer you the right materials and deliver to you very quickly.

Q: How Thick Can 4140 Plate Be?

A: 4140 Plate can come in different thicknesses. It can be as thin as 1mm (about the thickness of a pencil) or as thick as 300mm (like a big book). We keep 4140 plate stock for most of those thickness with immediate shipment.

Q: Why Does the Thickness Matter?

A: The thickness of the 4140 Plate matters because different applications need different thicknesses. Some applications need a thicker plate to make things stronger, while other applications might need a thinner plate.

Q: Can I Get a Custom Thickness?

A: Yes, you can get 4140 Plate in the thickness that fits your needs. Just let us know what you need, and we can make the official offer for you.

Q: Is Thicker Always Better?

A: Not always. Thicker plates are often stronger but might be too heavy for some uses. It depends on what you need the plate for. The right thickness is the one that fits your project.

Q: How Can I Find Out the Right Thickness for My Project?

A: If you’re not sure what thickness you need, you can talk to us. We have lots of experience with 4140 Plate and can help you pick the right thickness for your project and deliver to you very soon.

What is 4140 Steel Plate?

4140 steel plate is a type of strong metal plate made with elements like chromium, molybdenum, and manganese. It’s famous for being very tough and able to handle a lot of wear and tear without breaking or twisting.

1. Understanding 4140:

Grade 4140 is one kind of alloy steel in ASTM standard. Steel 4140 is a specific type of steel that contains elements like chromium and molybdenum. These elements give 4140 steel special properties that make it strong and versatile.

2. Different Conditions of 4140 Steel Plate:

4140 plates can come in different “conditions.” There are three condition of 4140 plates available in Otai:

- Hot Rolled: It’s the original condition after manufacturing as

- Annealed: Annealed 4140 alloy steel plate is softened by heating and cooling. Imagine heating chocolate, then letting it cool slowly. This makes the steel easier to shape and work with.

- Q&T (Quenched and Tempered): 4140 steel in QT condition has been hardened by heating and cooling quickly, followed by reheating. Think of it as making the steel extra tough, like turning soft clay into a hard, baked clay pot.

3. What Can You Do with 4140 Steel Plates?

You can do a lot with 4140 plate! It’s used to make tools, machinery, vehicle parts, and even some buildings. Because it’s strong and can be shaped in different ways, it’s like a handy helper for many projects.

4. Why Choose 4140 Steel Plate?

Steel plate 4140 is popular because it’s strong, flexible, and can be adapted to many needs. We also keep extensive 4140 plate stock and it delivers quickly.

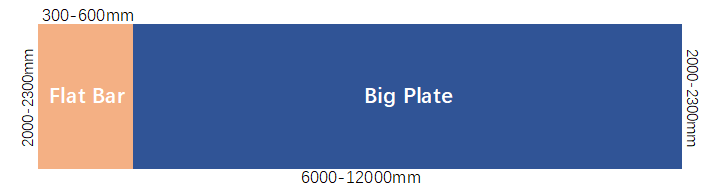

As a supplier of 4140 plates, we can supply you 4140 steel plate in different tolerance as below:

- Black surface 4140 plate: the thickness tolerance usually goes +/-1mm while the width is usually 2000-2300, mostly pieces are 2200-2250mm. We can cut to length for you.

- For 4140 group flat bar: we can do machining for you according to given specification or technical requirements. With our CNC machine, we can do +/-0.05mm and 0.01mm after polishing machining.

So, for tolerance for 4140 plate, we can almost meet your different requirements. Please feel free to contact us by email jeremy@otaisteel.com or whatsapp +8613610149979 anytime.

Actually 4140 steel is neither carbon steel nor stainless steel. AISI 4140 steel is one kind of alloy steel in ASTM standard A29 or A331 or A108 spec.

To tell one steel is stainless or not, we can see the chemical composition. Stainless steel usually contains min 13% chromium, less than 1.2% carbon and other alloying elements. While stainless steel’s corrosion resistance and mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

AISI 4140 steel contains 0.80-1.10% chromium, so you can see 4140 steel is not stainless steel.

One US customer asks one question about 4140 plate: is 4140 steel good for knives ?

Actually 4140 steel plate is not commonly used for knives. For general purpose of knives, we can use grade such as 1045 for knives. And we can use grades such as AISI D2 / DIN 1.2379 or high speed steel grades HSS for high end applicant.

But for 4140 steel plate, you can find 4140 steel plate used for many industries, including the defense, agricultural, and automotive industries.

Some friend asks me Is 4140 A Tool Steel ?

Actually, AISI / SAE 4140 steel is a kind of alloy steel. But it’s a versatile steel material. Some people also use it as mold steel and tool steel. So, you can also call it 4140 tool steel. Especially, for 4140 plate, most of customers use 4140 steel plate as mold steel or tool steel purpose.

We can help if any 4140 plate is needed anytime.

Why all 4140 steel flat size from China with 2000-2300mm length ?

That’s because the produced ASTM 4140 big plate is with width of 2000-2300mm. So, when big plate is cut to required 4140 flat bar size, then big plate width becomes the length of flat bar.

You can easily understand with below picture:

What is Alloy Steel 4140 Plate Tensile Strength ?

Some customers ask for the 4140 plate tensile strength. In common rolled condition, the min tensile strength will be min 655Mpa. But generally, the strenghth is different with different heat treatment condition. So, you please check with us for your detailed requirements.

What is 4140 DCF Steel Plate ?

Decarb Free stands for DCF. It means 4140 steel plate has been ground top and bottom. It is oversized to finish on the thickness, without the black surface. DCF offers excellent wear resistance, combined with good deep hardening characteristics. Its ability to show low distortion or movement in heat treatment. It also makes this material an excellent product for many tool room applications where size stability is critical.

Can you Harden 4140 Steel Plate?

AISI 4140 alloy steel plate can be hardened by cold working, or heating and quenching or annealing. We keep alloy steel plate 4140 stock material in both rolled condition and quenching & tempering condition. While sometimes, customer also needs annealed condition and we will do annealing heat treatment on the as rolled plate.

Can You Weld 4140 Prehard Plate?

AISI 4140 steel is alloy steel with chromium and molybdenum. The addition of these alloying elements and its relatively high carbon content (around 0.40%) provide this low-alloy steel with excellent strength to weight ratio, and it also makes 4140 steel a lot stronger and harder than standard 1018 and 1020 steels. The disadvantage is the need to be more careful when welding 4140.

AISI 4140 steel plate is typically supplied in either the hardened and tempered condition (referred to as 4140HT or 4140H) or in the annealed condition. For welding it is recommended that you use the latter. But it is not recommended to weld on 4140HT plate due to the high susceptibility for cracking, even when using prehard 4140 plate.

What Does Alloy Plate 4140 HTSR Stand For?

HTSR stands for Heat Treated, Stress Relieved. For alloy steel plate 4140, it’s usually delivered as rolled, or prehard (Q+T) condition. But some customer will need it inside stress relieved. Then 4140 plate is heat treated, reduce brittleness and relieve any stress fractures throughout the 4140 steel plate or flat bar.

For preharden alloy steel 4140 plate, some customers would need to know what is the 4140 Prehard Alloy Plate Hardness?

Usually, it’s 28-32HRC hardness for 4140 prehard alloy steel plate. It’s designated as AISI 4140HT or 4140H. For prehard 4140 plate, we keep hundreds of tons in stock for immediate shipment. You have the hot rolled 4140 plate and prehard 4140 plate stock list.

Some customer asks, Is 4140 plate an alloy steel plate?

Well, AISI 4140 plate is a steel material containing chromium, molybdenum and manganese containing and it’s low alloy steel. So, yes, 4140 plate is an alloy steel plate. 4140 plate has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. Alloy steel 4140 plates are widely used for tooling, machine plates, molds, metal stamping, gears, shafts, sprockets, special machine parts, tool & die, shredders, couplings, reamer bodies, screws, flywheel components, axles, shafts, bolts, sprockets, piston rods and rams.

Is it ok for 4140 alloy steel plate mold steel ?

Some customers ask us if they can use 4140 alloy steel plate mold steel. The anwser is Yes ! It’s ok and widely used as mold steel, such as 4140 alloy mold for car industry. It’s more widely to use 4140 steel plate as mold base. Alloy plates 4140 and other steel like P20, 4130, have a hardness at 28-34 HRC and have good mechanical properties. They are perfect for cavity and core plates as well as other plates required in the mold base. They can be machined fairly well. You can check our 4140 alloy steel plate stock at this page for any alloy steel 4140 plate request.